Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Aerogel Insulation Production

Introduction

In today's world of advanced thermal management, aerogel insulation is gaining global attention as one of the most efficient and lightweight insulating materials. Known for its ultra-low thermal conductivity and exceptional performance in extreme environments, aerogel is revolutionizing how industries approach insulation challenges.

This blog explores the aerogel insulation production process, its applications, types, and what industrial buyers and procurement managers should know when sourcing from global manufacturers—especially from China, one of the largest producers of aerogel materials.

What Is Aerogel Insulation?

Aerogel insulation is a high-performance material derived from a gel in which the liquid component has been replaced with gas without causing collapse of the gel structure. The result is a solid material that is up to 99.8% air, giving it incredibly low thermal conductivity.

Key Properties:

-

Thermal Conductivity: As low as 0.013 W/m·K

-

Lightweight: Among the lowest densities of any solid

-

Hydrophobic: Resists moisture absorption

-

Fire Resistant: Non-combustible and high-temp stable

-

Flexible (with reinforcement): Can be fabricated into blankets or composite sheets

Aerogel Insulation Production Process

The production of aerogel insulation materials involves multiple high-tech steps. Here’s an overview of the general process:

1. Sol-Gel Process

The base materials, typically silica precursors (e.g., tetraethyl orthosilicate), are mixed with a solvent and catalyst to form a gel. This initial step defines the porous network structure.

2. Aging

The gel is aged to strengthen the network and improve thermal and mechanical stability.

3. Solvent Exchange

The solvent in the gel is exchanged with a low-surface-tension fluid, often ethanol or acetone, to prepare for drying.

4. Supercritical Drying / Ambient Pressure Drying

Two major drying methods are used:

-

Supercritical Drying: Preserves the pore structure by drying above the critical point of the solvent.

-

Ambient Pressure Drying (APD): Uses surface modification to reduce capillary forces, enabling low-cost drying.

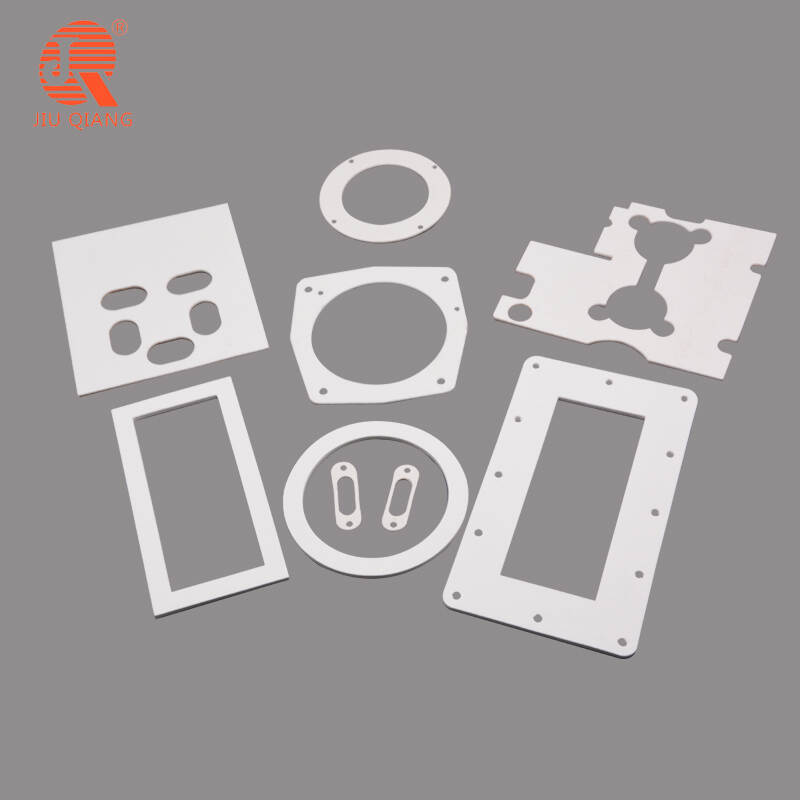

5. Post-Processing and Reinforcement

The fragile aerogel is reinforced with fibers (e.g., fiberglass or ceramic) to create aerogel blankets, sheets, or panels. Coatings may be added to improve hydrophobicity or surface strength.

Types of Aerogel Insulation Products

1. Silica Aerogel Blankets

The most common type. Reinforced with fiberglass or ceramic fiber and used in LNG pipelines, industrial furnaces, and power plants.

2. Carbon Aerogel

Used in electrochemical applications and high-tech energy systems. Offers excellent conductivity and thermal performance.

3. Polymer-Based Aerogel

More flexible and lower cost, used in consumer electronics, apparel, and HVAC insulation.

4. Composite Aerogel Panels

Sandwiched structures that combine aerogel with aluminum foil, fiberglass, or other materials for structural insulation.

Applications of Aerogel Insulation

Aerogel’s unique properties make it ideal for a wide range of applications:

-

Oil & Gas Pipelines (especially LNG)

-

Industrial Process Equipment

-

Cryogenic Insulation

-

Aerospace and Defense

-

Automotive Heat Shields

-

Construction & Green Buildings

-

Wearable Insulated Apparel

Why Is Aerogel Insulation a Game-Changer?

-

Energy Efficiency: Lower heat loss, reduced energy bills.

-

Space Saving: Requires less thickness to achieve the same R-value.

-

Fire Safety: Withstands extreme temperatures without combustion.

-

Durability: Long-lasting even under mechanical and chemical stress.

Aerogel Insulation Production in China

China has become a leading hub for aerogel insulation production, offering both mass manufacturing and OEM customization. Advantages of sourcing from Chinese aerogel manufacturers include:

-

Competitive Pricing: Due to raw material access and scale of production.

-

Advanced Facilities: Many suppliers have adopted supercritical drying and composite technologies.

-

Customization: Sizes, densities, coatings, and packaging tailored for various industries.

-

Export Experience: CE, ASTM, ISO certifications, and global shipping logistics support.

How to Choose a Reliable Aerogel Insulation Supplier

When sourcing aerogel insulation, especially for industrial or OEM use, consider the following:

1. Product Consistency

Ask for datasheets, batch reports, and sample testing to verify thermal conductivity, density, and tensile strength.

2. Production Capacity

Ensure the supplier can meet large volume needs with consistent lead times.

3. Export Capability

Suppliers should be experienced in handling international shipping, certifications, and customs paperwork.

4. Technical Support

Professional suppliers offer engineering consultation, usage guidance, and after-sales service.

5. OEM / Private Label Options

If you plan to rebrand or integrate the product, choose a manufacturer that supports OEM services and NDA agreements.